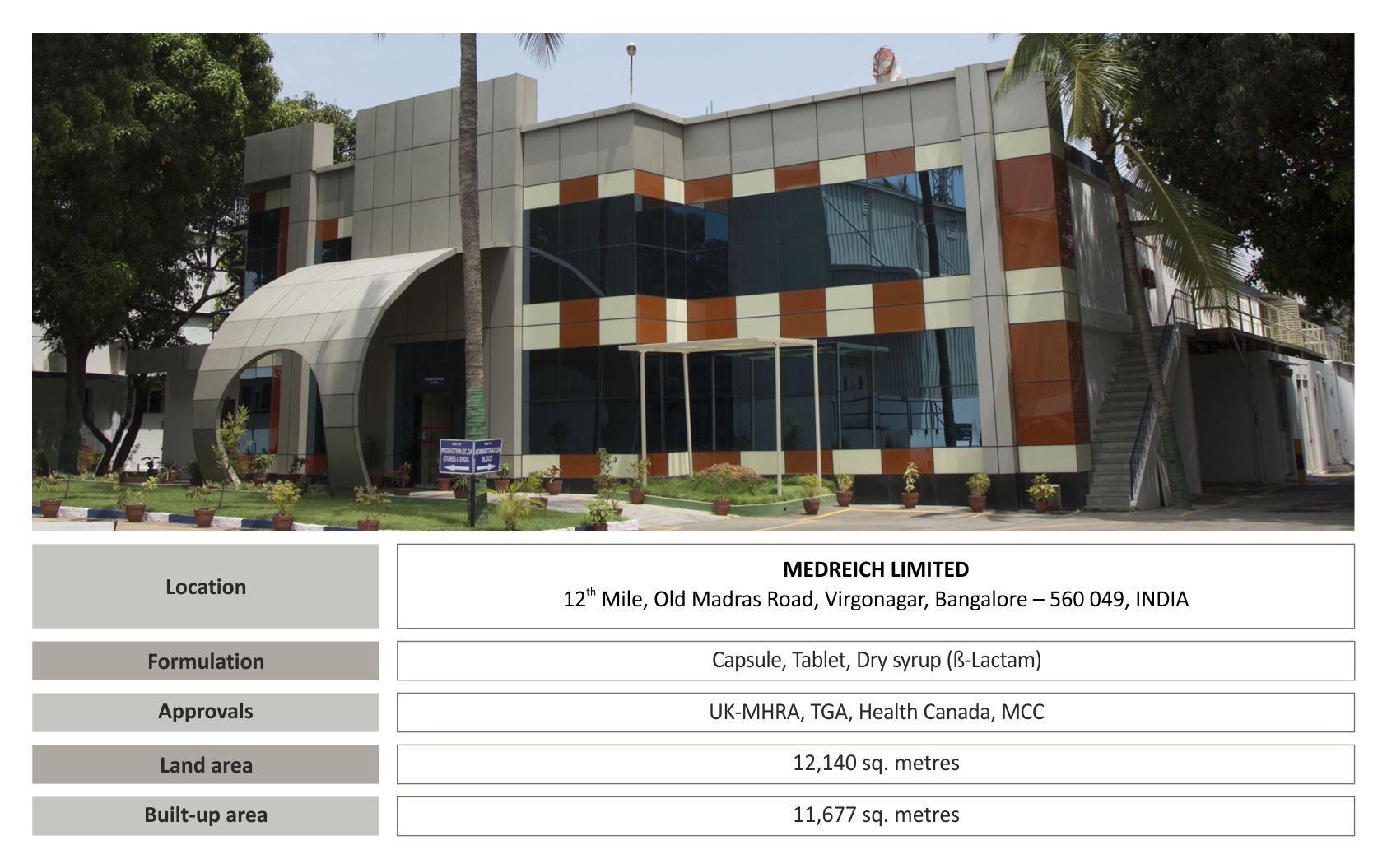

Seven State of the art manufacturing facilities complying with stringent Regulatory and EHS requirements of several developed markets.

The Facilities are approved by various Regulatory authorities including UK MHRA, TGA AUSTRALIA, HEALTH CANADA, PMDA Japan, MFDS south Korea, MCC SOUTH AFRICA, GCC, PICS compliant and ROW markets of Africa and Latam.

All the manufacturing facilities have unidirectional flow of man and materials movement and capable to manufacture various dosage forms like Tablets, Capsules, Dry Powders for suspensions, Dry powder for Injections etc… under stringent GMP environment conditions. The facilities are equipped with latest equipments to manufacture the products as per the international Regulatory standards.

All the units operate under Quality Management System (QMS) as per International guidelines and eQMS system has been implemented to facilitate the QMS for continuous improvement.

All plants have Independent full-fledged Quality Control Laboratories which consists of instrumentation, chemical, microbiological and packaging material testing sections. Quality control operations are handled through Quality Laboratory Management System (QLMS) enabling direct capture of data from the equipment to reduce human intervention and errors.

Dedicated storage areas are in place for raw materials, packing materials and finished goods as per the storage condition requirements.

Two stability centers equipped with walk–in chambers to perform stability studies for all the Zones as per ICH guidelines.

The entire operations from the customer order entry till the dispatch of finished goods is on SAP platform.

Environment Health and Safety (EHS) measures are in place as per global standards. Facilities are equipped with Effluent Treatment Plant, Fire hydrants system, Emergency Response plan, to provide a safe and healthy working environment.

Dedicated Operational Excellence team (OE) in place for continuous improvement through tools like Six Sigma, Kaizen etc..